Discover the Importance of Having Your Machines Lubricated

With the huge demand on today’s market, many manufacturers in different industries rely on their machinery working in top condition with maximum efficiency. But in order to do so, the machines need to be consistently and correctly lubricated. Lubrication engineers report that more than 50% of all bearings are due to lubrication methods that aren’t proper. It’s said that a well-oiled machine is a profitable machine.

Lubrication can certainly increase your profits and give you more opportunities. For instance, if a plant’s total sales are $50 million and the downtime because of improper lubrication is 20%, you’ve lost $1.25 million. Lubrication can add or subtract from this opportunity, and good lubrication practices will preserve and protect assets and it will keep them generating profits and products.

When it comes to lubrication, usually longtime employees are the ones that are given the task by most companies. However, human memory is fallible and companies slowly turn to computerised maintenance systems, which are overall effective but don’t provide streamlining and detailed tracking of lubrication costs and tasks.

And when we speak about lubrication, it’s not a single activity we’re talking about but this covers a rather wide range of activities related to oil, grease, handling of lubricants, lubrication pumps and other equipment, oil analysis, lubrication devices, breathers, etc.

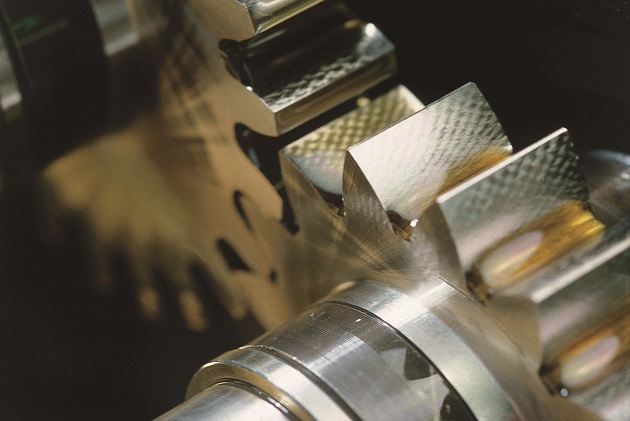

Lubrication does much more than keeping surfaces slick and slippery. More importantly, it provides coating to prevent metal-on-metal contact between moving parts. No matter how smooth and polished the surfaces of these parts are, they have rough surfaces at microscopic levels, so tiny peaks stick out and scrap against each other, causing friction which interferes with smooth motion. Moreover, it causes heat and increases surface wear which can lead to equipment failure. The layer created by lubrication is like a layer of film between the parts and that thwarts friction, which in turn promotes smoother operation and a prolonged lifespan of the equipment.

The protective layer also helps to safeguard component surfaces against corrosion and rust by preventing them from coming in contact with corrosive substances like water. Furthermore, lubricants also serve as conduits that carry away and suspend contaminants to separators like filters in the system where they can be removed without harming components.

And lastly, lubricants absorb heat by drawing it away from surfaces. Many machines, depending on their application can heat up to extreme levels, and lubricants can dissipate that heat or transport it to a cooling device. Anyhow, lubricants help you keep operational temperatures balanced and they reduce the risk of heat damaging the machine components, which makes lubrication pumps more than important for the proper functioning of machines.