Discover the Intricacies of Engine Swaps

There are many reasons why you might want to swap your vehicle’s engine for a brand new or used one. Regardless of your reasons, swapping an engine can bring new life to your vehicle and extend its longevity significantly. There’s no way to talk about the details of every engine swap process, but I’ll try to do my best to answer some of the most commonly asked questions people who want to swap their engines have asked me throughout the years. Throughout my career working as a mechanic, I’ve seen some great engine swaps, and I’ve seen some terrible ones. That being said, if you want to make sure you swap your engine properly, or you just want to find out some information about engine bolts and nuts for the process, I’ll cover all of that today.

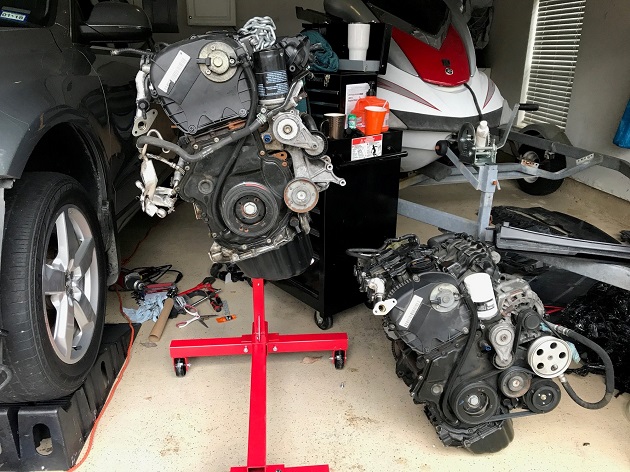

What’s an Engine Swap?

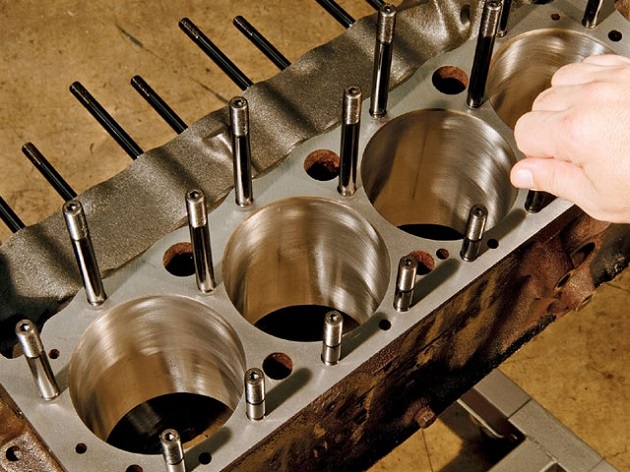

An engine swap is basically the replacement of your original engine with a new one. This is typically done to improve performance, although they’re sometimes done to replace a broken engine. If you’ve decided to swap your engine, you have two choices. You can either swap it with an engine designed for the type of car you have, or swap it with a completely different one. As you might guess, swapping your engine with a completely different one is much more complicated than swapping it with a manufacturer-approved engine. It will require more effort and money, because you’ll probably end up modifying your car quite a bit. You’ll need different engine bolts, nuts, and other hardware parts, and you may need more space under the bonnet.

Are Engine Swaps Difficult?

Installing a brand new engine in a used car…surely nothing can go wrong, right? Well, quite the contrary. There are many things that can go wrong, and most people think that all they have to do is just bolt it in. In all my years working as a mechanic, I’ve never seen an engine swap go as smoothly as I had originally hoped. That’s just how it is, and it’s the main reason why most people leave the process to a professional. It’s a process that requires due diligence and preparing, as well as a lot of time spent under the bonnet. Furthermore, it requires fabrication skills, and that’s just to ensure you mount it properly. Once it’s mounted, you’ve only done part of the job. You need to make sure the power produced by the engine is transferred to the wheels properly, which can require even more modification to the transmission. On top of all that, you’ll need to get coolant and air into the engine, meaning you’ll have to connect the engine properly to all the other parts under the bonnet, such as the radiator.

But there’s more! You’ll have to ensure the engine sends electronic signals to the dashboard, so you’ll also have to do a fair amount of wiring. If you do this improperly, your pedals may decide to stop working. And in all my years of experience, I’ve never seen a person do the wiring properly, at least not on the first attempt.

Can You Swap a Diesel Engine To Gas?

This is probably the most frequently asked question at my shop. The answer is yes – you technically can, but it will require a ton of work and things to keep in mind. For starters, diesel engines are heavy, so if your vehicle had a gas engine up to this point, will it be able to preserve its structural integrity? Will the diesel engine fit in the engine bay in the first place? Or will you require a scoop? If you plan on increasing your horsepower, you’ll need to think about the axles, as they won’t be able to withstand the torque that comes from a more powerful engine. The same thing applies to the transmission. If you’re getting a mechanical engine, you won’t need to pay mind to the electronics. If you’re getting an electronically controlled engine, however, you’ll need to find a way to speak to the transmission. Last but not least, you’ll have to consider the emissions, and potentially undergo extra inspection requirements, depending on where you live.

How Much Will an Engine Swap Cost?

The answer to this question will come down to a lot of factors, and there’s never a single answer that can cover all of these factors. It will depend on whether you’re swapping in a mass-produced engine that’s suitable for your vehicle or not. Generally, the price for swapping an engine can range anywhere between $2000-$5000. The new engine and the work by the mechanic are included in this price. You can save a decent amount of money if you do it yourself, but that will require a lot of work and expertise, and most people aren’t familiar with engine work.