Discovering How Camshafts Work

Not a lot of people are even aware of what a camshaft is, let alone what it does. It’s definitely one of the most important pieces in the car’s engine, and yet, not everyone is fully aware of it. Its function is to open and close the valves at the top of each cylinder within the engine, which is more complicated than it seems. It’s one of those automobile topics that everyone needs to at least be aware of, like diesel engine catalytic converters, because it’s such an important part of the combustion process. There are quite a few things you need to know, which is why we’ve compiled this handy guide for you.

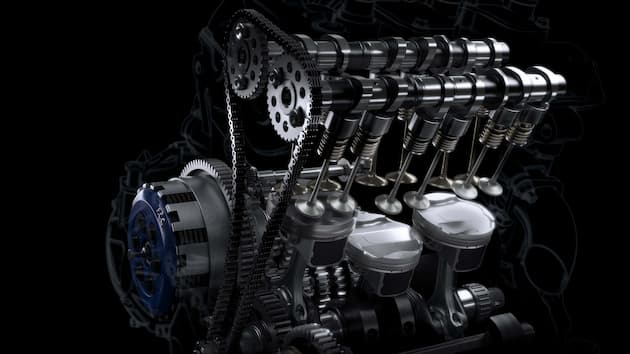

Camshaft Basics

The most important parts of any camshafts are the lobes. When the engine camshaft spins, the lobes open and close the intake and exhaust valves in time with the motion of the piston. That’s because there is a direct correlation between the lobes’ shape and engine performance. To visualise this, imagine that an engine is running extremely slowly at 10 or 20 RPM. That means it would take the piston a couple of seconds to complete the cycle. At this slow speed, we would want cam lobes shaped so that would close the intake valve right as the piston bottoms out and would close the exhaust valve as the piston completes the exhaust stroke. Any given camshaft will be perfect only at one engine speed. At every other engine speed, the engine won’t perform to its full potential. That’s why a fixed camshaft is always a compromise. This is why carmakers have developed schemes to vary the cam profile as the engine speed changes.

Configuration

There are a few different configurations to be aware of.

Single Overhead Cam

This arrangement means an engine with one cam per head. So if it is a 4 or 6-cylinder engine, it will have one cam; if it is a V-6 or V-8, it will have two cams. The valves are pressed down by the actuated rocker arms by the cam that open them. Then the springs return the valves to their closed positions very quickly. If the springs were not strong enough, the valves might come away from the rocker arms and snap back. That’s something to avoid because it can cause significant wear and tear on the cams.

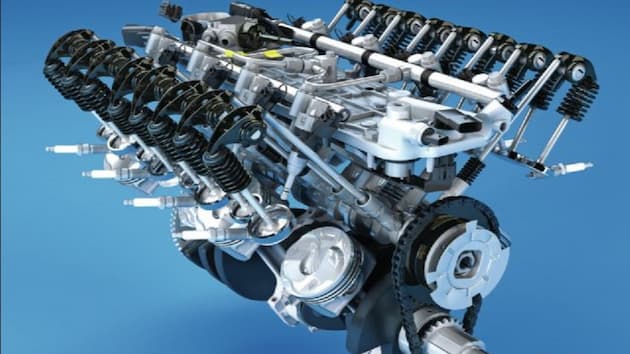

Double Overhead Cam

If you have a double overhead cam engine, then that means it has two cams per head. For example, inline engines have two cams, and V engines have four. Usually, double-overhead cams are used on engines with four or more valves per cylinder — a single camshaft doesn’t have enough space to have enough cam lobes in order to actuate all of the valves. The main reason to use double overhead cams is to allow for more intake and exhaust valves. More valves means that intake and exhaust gases can flow more freely because there are more openings for them to flow through. The end result is increased engine power.

Pushrod Engines

Like the previous two types, the valves in a pushrod engine are located in the head, above the cylinder. The key difference is that the camshaft on a pushrod engine is inside the engine block, rather than in the head. The cam actuates long rods that go up through the block and into the head to move the rockers. These long rods add mass to the system, thus increasing the load on the valve springs. This can limit the speed of pushrod engines; the overhead camshaft, which eliminates the pushrod from the system, is one of the engine technologies that made higher engine speeds possible.

Variable Valve Timing

Valve timing is a potential issue that needs to be solved efficiently, which is why different car makers have devised different solutions. Variable Valve Timing and Lift Electronic Control, or VTEC, is a system used in some Honda engines that allows the engine to have multiple camshafts. These engines have an extra intake cam with its own rocker, which follows this cam. The profile on this cam keeps the intake valve open longer than the other cam profile. At low engine speeds, this rocker is not connected to any valves. At high engine speeds, a piston locks the extra rocker to the two rockers that control the two intake valves. Some cars use a device that can advance the valve timing. That doesn’t mean the valves are open for longer, but rather they’re opened later and closed later. This is done by rotating the camshaft ahead a few degrees. If the intake valves normally open at 10 degrees before the top dead centre and close at 190 degrees after TDC, the total duration is 200 degrees.

What can go Wrong?

Camshafts are moving components, so they’re subject to wear and tear. The lobes can wear over time and the entire system around the camshaft can slowly deteriorate if it’s not maintained. If subjected to oil leaks from the system, or dirt and debris from the outside, then the system can be damaged. The camshaft sensor can also break down because it’s an electronic device that’s used by the vehicle’s engine management system. If the camshaft sensor is faulty, then the car might have ignition problems. The biggest damage can be done if the movement timing between the crankshaft and camshaft is off. In that case, the pistons and valves can crunch together and damage the entire engine.