Exhaust Wraps: Types, Benefits and Alternatives

Heat is how engines produce power. While engine efficiency has improved, still a large portion of heat resulting from the combustion process is lost, mostly through the engine block, exhaust manifolds, and in cars with forced induction, the turbo manifold. Estimates are that temperatures average 120 degrees Celsius at moderate engine RPMS, and well over 600 degrees during higher engine loads and speeds. This in itself can cause significant problems, with radiating heat impacting the integrity and performance of related parts and systems, like nearby hoses and electrics.

Containing excessive temperatures (the more powerful the engine the higher the temperatures) at the source has multiple benefits. It prevents damage to adjacent parts and also brings a tangible power boost. Different solutions are meant for different engine and vehicle parts. If you’re worried about exhaust valves, the exhaust manifold and the piping, consider applying durable exhaust wraps. This simple yet efficient product is derived from racing and extensively used in high-performance cars. The good news for car enthusiasts, tuners and anyone rebuilding a classic car, is that the material is readily available to wider motoring public, along with all the benefits it provides.

Exhaust Wrap Basics

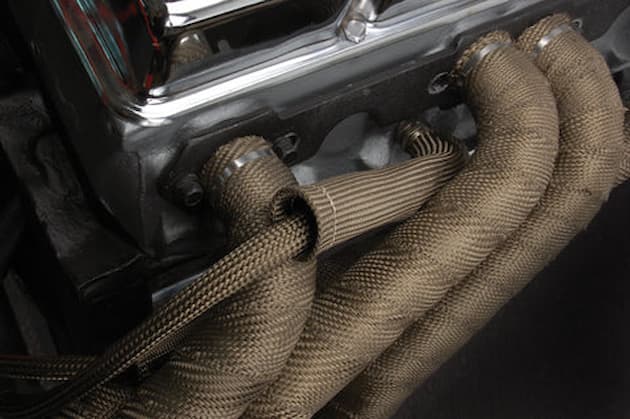

Exhaust wrap is a specialised thermal barrier made of woven layers of heat-resistant materials, including fibreglass, ceramic and basalt rock fibres. Its main use is to keep combustion heat within the exhaust system, and preventing it from radiating to nearby engine, transmission and chassis parts. By containing heat in manifolds and the exhaust piping, exhaust wraps also improve exhaust flow and velocity, thereby reducing heat stress on the engine. This results in a more efficient engine capable of producing more power.

Benefits the Material Provides

- Efficient heat management: Keeping heat within the exhaust tubing means spent gases are hotter and exit the vehicle faster, leading to potential performance gains. Insulating metals in the exhaust system also reduces expansion and contraction with varying temperature ranges (or heat cycling), considerably reducing the risk of stained, cracked or defective exhaust parts.

- Localised heat soak: This is radiant heat reaching adjacent parts. Wrap protects sensitive materials and components like wiring, sensors and rubber hoses, from overheating, cracking, fraying or melting. A related result is that heat also doesn’t penetrate firewalls into the cabin, meaning a cooler, more comfortable ride.

- Increased power and torque: Wrap keeps exhaust gases hot, increasing their velocity and aiding the engine by producing a scavenging effect (or high pulsating and low-pressure areas that act like a vacuum to draw spent gases out faster). This has tow beneficial results. One is improved exhaust flow, the other is reduced intake temperatures. Cooler air on the intake side of the engine is denser and oxygen-rich and increase combustion efficiency with better burns.

- Sound insulation: wrapping parts reduces the likelihood of vibrations and accompanying noises.

- Safety: For tuned cars, trucks and motorcycles, exhaust wrap prevents burns and injuries during regular servicing and maintenance.

- Aesthetics: a variety of colours and textures make the materials visually-pleasing, especially in car rebuilds, tuning projects and exposed motorcycle exhausts.

Choosing the Wrap You Need

There are several types of exhaust wrap, all differing in thermal protection, chemical properties, appearance and purpose. The cheapest but still effective option is fibreglass exhaust wrap, ideally used in managing radiant heat in unmodified engines, with effective thermal protection of temperatures up to 500 degrees Celsius. While cheaper than other options, fibreglass wrap needs to be pre-wetted in water to ensure good adhesion to the piping and reduce fraying or cracking due to its brittleness.

Wraps made from crushed basalt rock are more durable, resist temperatures to 750 degrees and benefit from being non-toxic and completely recyclable. These are good for engines with forced induction, easily containing the extra heat that comes from turbines and superchargers. For high-performance, high-output vehicles, the best choice is titanium wrap. This a premium option that is very durable, pliable, easy to install, resists short periods of extreme temperatures (to 2000 degrees) and has the highest continuous temperature rating of any exhaust wrap currently sold, at1200 degrees.

The three types also differ in colours. Fibreglass is in lighter tones, usually white, basalt rock wrap in black and titanium wrap in gold. If you’re matching engine bay or motorcycle upgrades, this is something to consider. Lastly, get wrap in the right length and width for the application. Usually this differs between exhaust wrap intended for primary piping such as the headers, downpipes and catalytic converters, at 25mm in width, and wrap intended for the rest of the tubing, at 50mm. Rolls of 15 to 20mm will be each for both motorcycles, and larger-displacement car engines.

Combining Wrap with Heat Shields

Exhaust wrap is effective on its own, but for engines that produce a lot of heat, consider combining the material with exhaust heat shields. These are thin (3mm) thick aluminium (or aluminium-backed fibreglass) sheets that are used to reflect radiant and convective heat back to the heat source, thus protecting sensitive components like fuel pumps, brake lines, wiring and the the floor pan. Source this and wraps in the right type and size for your application from exhaust parts and tuning specialists.