Guide to Warning Lights: Ensuring Safety in the Workplace

Injuries and fatalities have plateaued in Australian workplaces, mostly because of stringent safety regulations, despite growing workforce participation. Signs, lights and containment kits are all there to keep employees safe and reduce potential property damage and environmental hazards. State and federal WorkSafe bodies define the need for appropriate workplace lighting as one where employees can work without risk to personal health and safety, move safely around the workplace and evacuate the premises during emergencies.

The purpose of lighting is to make potential hazards and safety risks evident at all times and inform employees of different procedures and activities taking place, while also being appropriate for the work being done and the specifics of the workplace. In this context, industrial warning lights have contributed to reducing the number of sustained injuries in areas such as warehousing, construction, and mining.

Types of Warning and Emergency Workplace Lighting

Lights in typical industrial (and by extension, commercial) settings can be grouped into flashing strobe, rotating beacon and pulsating warning lights. Each serves a particular function, but all are tasked to increase safety.

Strobe Lights

These produce short flashes of high-luminance light. They have a high signalling effect of bursting light in colours that can be tailored to specific needs. They are found in areas like warehouses and numerous industrial facilities, specifically on moving machines and equipment, service vehicles, material handling equipment, security gates and more.

Flashing strobes are often used in emergencies, including fires, chemical spills and leaks, as well as machine and equipment failures caused by interrupted power supply or electrical faults.

Beacon Lights

Beacon warning lights produce an uninterrupted light with a consistent intensity. They come in two major types – fixed and rotating. Fixed types are often used to signal stages in production processes, such as when machinery is on. Rotating lights are a common feature in construction and vehicles and equipment used in material handling, like forklift trucks and conveyor systems.

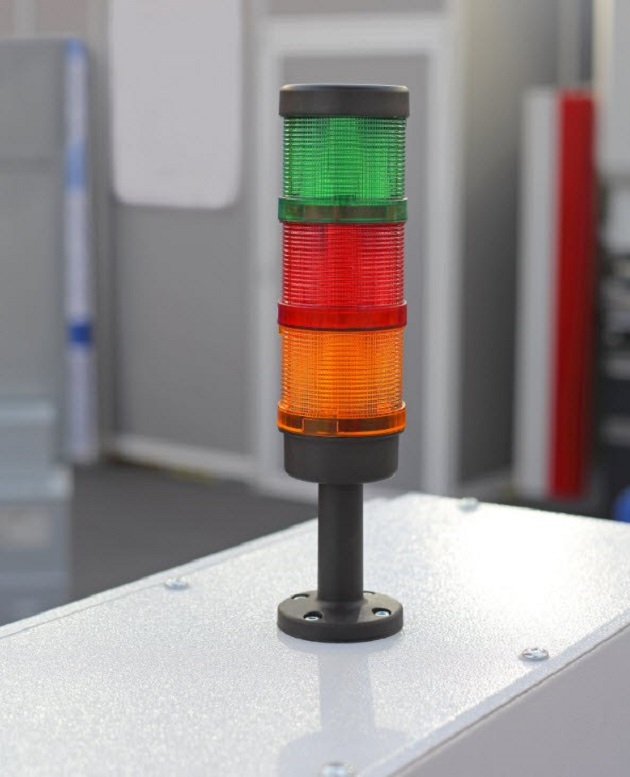

They’re also standard on emergency vehicles, on aeroplanes and boats, and in railroad networks. Lights can be used on their, in a stacked configuration and are part of a comprehensive warning and signalling system that also includes sirens and alarms.

Pulsating Lights

These are a type of beacon light shining in a pulsating or blinking sequence. They’re usually reserved for particular areas with high hazard levels, such as heavy-duty machinery, mines and construction sites. And you’ll also find them atop communication masts and buildings directing air traffic.

The Importance of Colours

Signals and messages warning lights convey can be understood from the use of different colours. Like the different types of lights, colours warn of different danger levels:

- Red – is recognised as the universal colour for danger, and in typical industrial settings warns of imminent hazards and risks from machinery and equipment operating nearby. It is also a standard feature on ambulances and fire trucks.

- Yellow/Amber – this signals caution or that changes in operations or circumstances can lead to danger. You’ll see warning lights shining in amber on construction vehicles, forklifts, and doors and security gates in production sites.

- Green – means security or safety, or that a previous safety issue has been resolved. On machinery, it can also mean that production is underway.

- Blue – this is an alternative to red, and in industrial settings often signals that a change will happen, such as equipment powering down.

- Magenta/purple – signals the need for awareness of an immediate danger or hazard, such as a fire or explosion, or that action needs to be taken to prevent harm.

- White – these lights are used in cases of extremely low visibility, and often as an alternative to red to signal danger.

Buying Considerations

Lighting tech, build and materials are the main considerations when buying warning lights. LEDs are now the standard feature in most types, benefitting from easy colour calibration, low power use, and very long operating hours. Newer advancements have also meant they’re brighter. Xenon bulbs are a standard-duty alternative, though usually consume more power and can generate more heat, considerably affecting longevity and brightness output.

Lights can be optioned in a range of materials to suit the settings. Explosion-proof versions seen in mining and construction, for instance, are built around robust aluminium housings, tempered glass lenses, steel guards and metal mounting brackets. Standard-use lights include polycarbonate lens covers and bases made of reinforced ABS plastic. Look for IP ratings that ensure optimal visibility when faced with dust, water, impact and temperature extremes, as well as industry certification, to ensure that they’ll last in typical working conditions. UV resistance is also applicable to lights used outdoors.

Lastly, get lights that are sized for the application, and come with compatible mounting hardware. Here the basic difference is between standard and low-profile types and lights that can be stacked one atop the other. There are also differences in mounting. Magnetic bases easily attach to ferrous surfaces, and can be removed and moved as needed. Fixed lights come with bolts that secure bases to equipment or machinery or pipe clamps when fitted to concave surfaces.